Predictive maintenance with PRTG

Keep an eye on your IT/OT infrastructure & inform your predictive maintenance strategy

- Monitor your IT, OT & IIoT infrastructure as a database for predictive analytics

- Collect & analyze historical monitoring data to improve predictive maintenance management

- Get custom alerts to solve equipment failures and other issues before they become critical

PRTG predictive maintenance: What you’ll find on this page

PRTG makes predictive maintenance as easy as it gets

Custom alerts and data visualization let you quickly identify and prevent potential issues before they actually happen.

How PRTG supports your predictive maintenance strategy

Comprehensive data for predictive maintenance

Collect and store historical data that can inform your predictive maintenance strategy and decisions. This is vital since maintenance operations and predictive maintenance rely on solid data.

How PRTG helps:

- Get data about your production processes directly from IIoT sensors by using webhooks, or by monitoring via the transmission protocols in use (such as MQTT, Modbus, or Redfish).

- Collect data from gateways, IPCs, PLCs, and other systems that run on OPC UA servers using the built-in OPC UA monitoring functionality in PRTG.

Custom alerts to act before your OT devices go down

Your proactive approach to maintenance needs a granular alerting system to ensure that the right teams are informed at the right time – not only when maintenance is due but also if there are unusual metrics that indicate a potential problem with a specific OT device or an entire production line.

How PRTG helps:

- Set custom warning thresholds for your PRTG sensors to identify emerging issues and resolve them before they become business-critical.

- Choose from notification methods such as SMS, e-mail, push notification, and more to make sure that you are alerted even while on the go (such as while inspecting the factory floor).

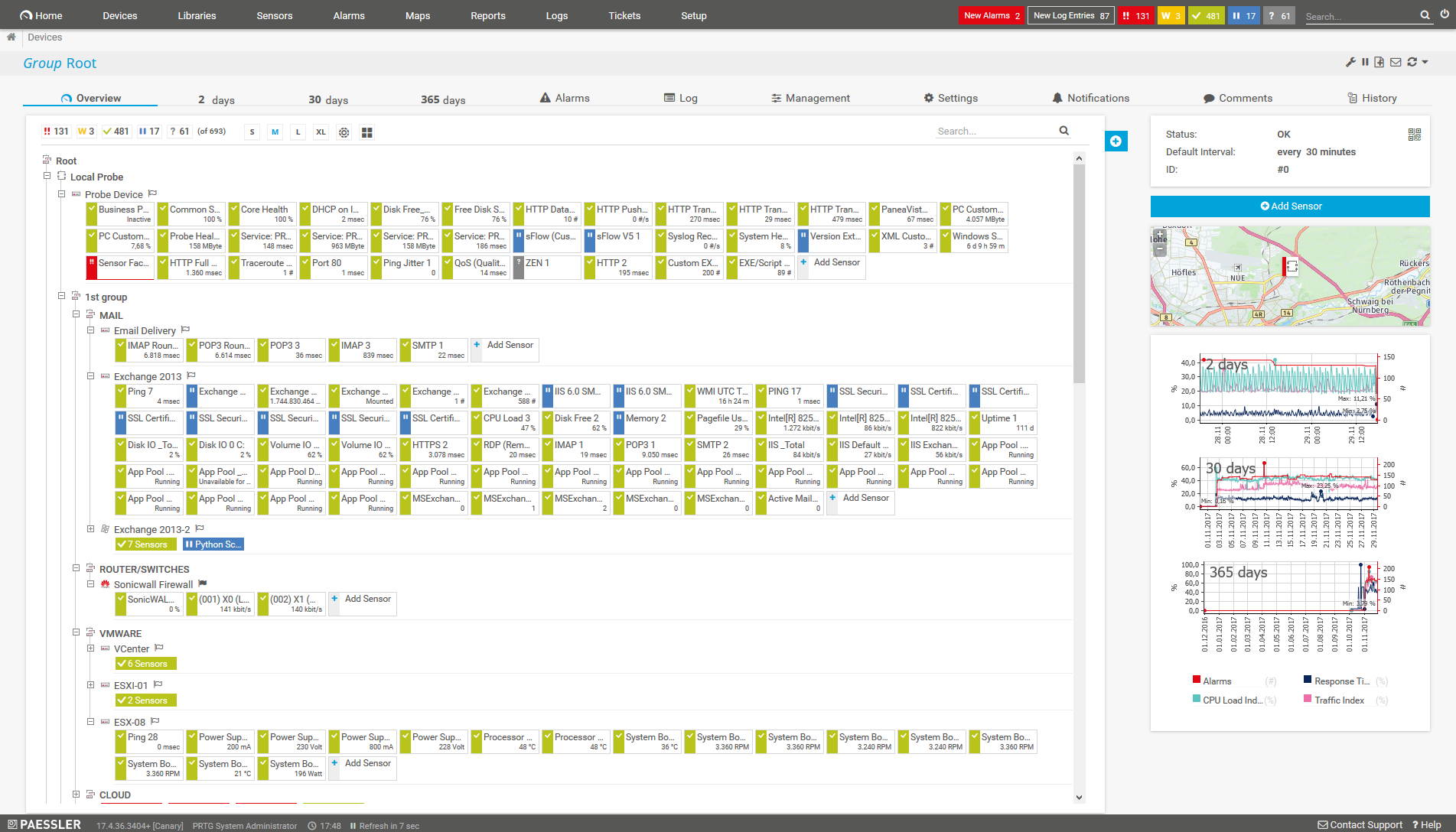

What predictive maintenance support looks like in PRTG

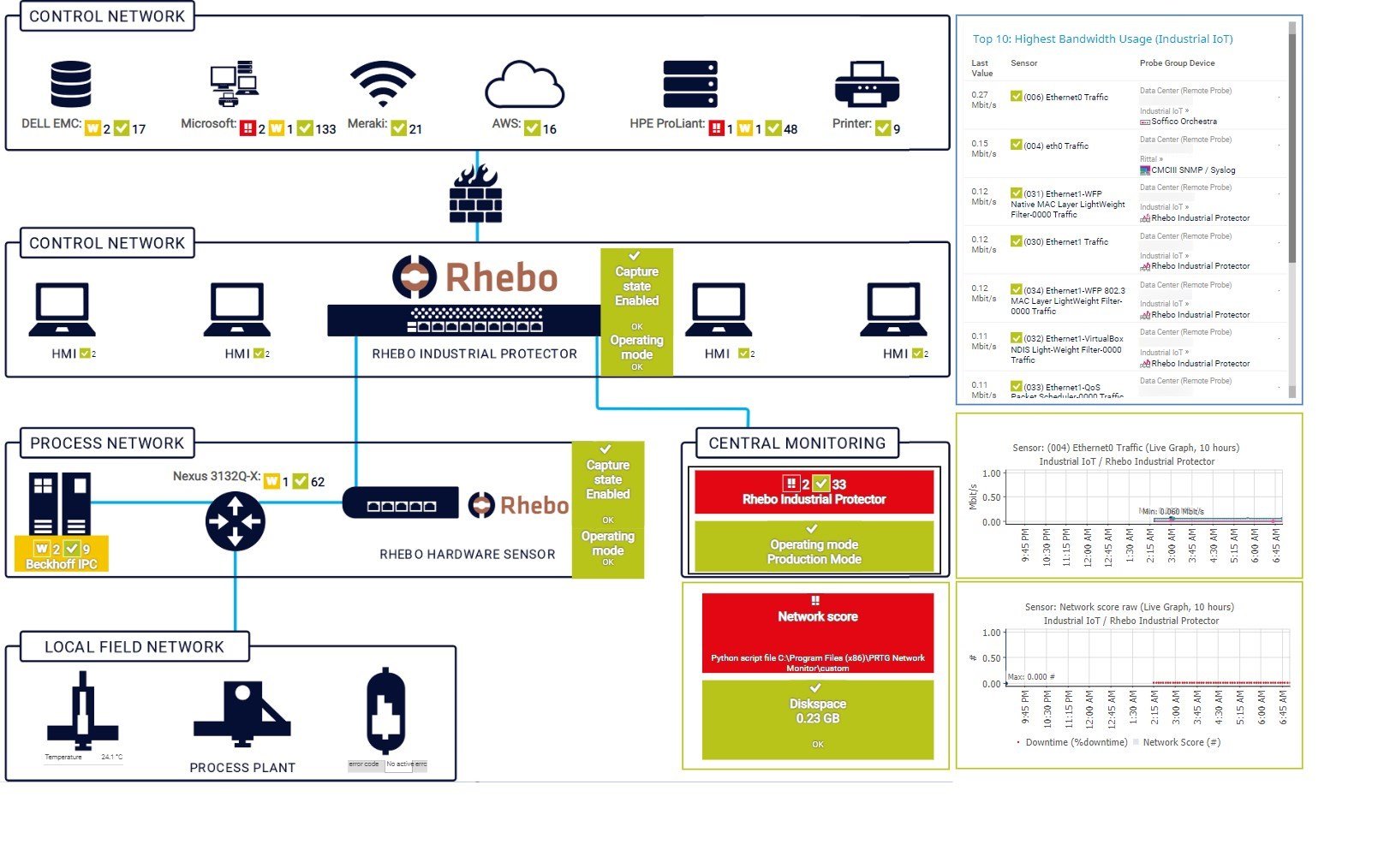

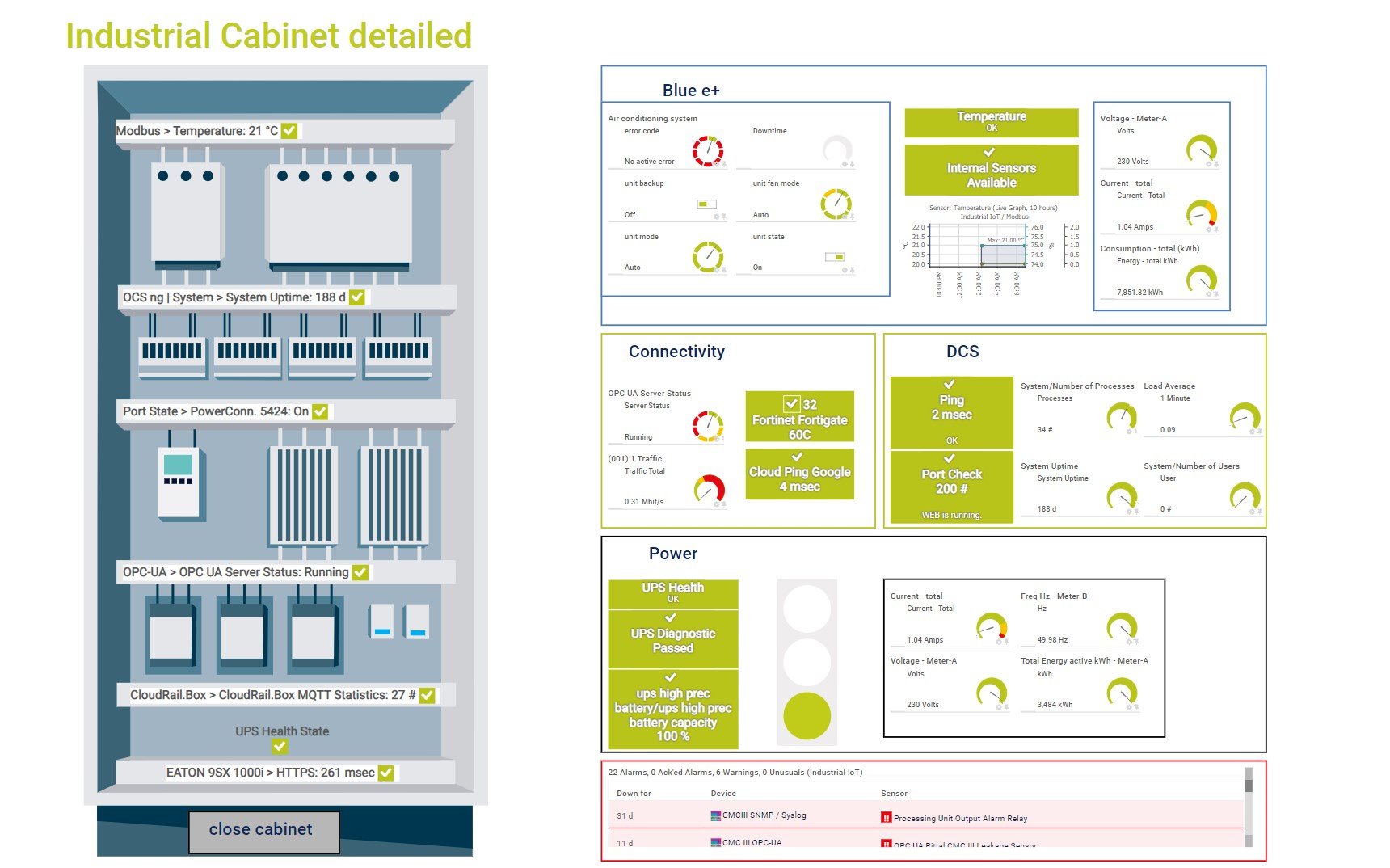

Diagnose network issues by continuously tracking IoT sensor data as well as your entire OT network. Show uptime, hardware health, equipment performance, maintenance processes, and other key metrics in real time. Visualize monitoring data in clear graphs and dashboards to identify problems more easily. Gain the overview you need to troubleshoot unplanned downtime, enhance the lifespan of your assets, and streamline workflows to enhance operational efficiency.

Start predictive maintenance with the help of PRTG and see how it can make your network more reliable and your job easier.

Keep an eye on the underlying IT/OT infrastructure with PRTG

While most maintenance maturity models focus on the equipment and machines on the factory floor, you must not forget the supporting IT/OT infrastructure. This includes the components that will collect real-time data about the production process and maintenance activities from the factory floor and transmit it to ERP systems or the cloud for analysis and processing. They form the basis of any OT maintenance strategy, and PRTG can help you monitor them.

IIoT sensors

IIoT (Industrial Internet of Things) sensors can make older machines “smart” (retrofitting), collect data analytics from the production line, monitor the health and performance of machines, regulate environmental conditions in the factory, and much more.

Monitor IIoT sensors to make sure they are functioning and transmitting data correctly.

Industrial Ethernet

The industrial Ethernet includes devices like routers, switches, servers, firewalls and more.

PRTG gives you monitoring functionality such as SNMP or flow-based monitoring to monitor the uptime, bandwidth usage, and much more of your industrial Ethernet devices.

Industrial gateways

Gateways are a key aspect of supporting infrastructure because they sit at the borders between OT and the outside world.

Categorized as edge devices, PRTG monitors their uptime and hardware metrics like CPU usage, open ports, and more.

Industrial enclosures

Enclosures house important devices and systems, such as industrial Ethernet devices, UPS systems, and more.

Keep track of the state of the devices inside and of the enclosure itself using informative dashboards in PRTG.

Your predictive maintenance program software at a glance – even on the go

Set up PRTG in minutes and use it on almost any mobile device.

Find the root cause of the problem with our PRTG predictive maintenance solution

Real-time notifications mean faster troubleshooting so that you can act before more serious issues occur.

PRTG is compatible with all major vendors, products, and systems

Explore our preconfigured PRTG sensors for predictive maintenance

PRTG comes with more than 250 native sensor types for monitoring your entire on-premises, cloud, and hybrid cloud environment out of the box. Check out some examples below!

Create innovative solutions with Paessler’s partners

Partnering with innovative vendors, Paessler unleashes synergies to create

new and additional benefits for joined customers.

Schildknecht

With condition monitoring and retrofitting, PRTG and Schildknecht DATAEAGLE make even older production plants competitive.

INSYS icom

With the combination of PRTG and Insys, the monitoring specialist Paessler and the industrial gateway manufacturer INSYS icom offer a practical possibility to merge IT and OT.

“Excellent tool for detailed monitoring. Alarms and notifications work greatly. Equipment addition is straight forward and server initial setup is very easy. ...feel safe to purchase it if you intend to monitor a large networking landscape.”

Infrastructure and Operations Engineer in the Communications Industry, firm size 10B - 30B USD

PRTG makes predictive maintenance as easy as it gets

Custom alerts and data visualization let you quickly identify and prevent potential issues before they actually happen.

PRTG: The multi-tool for sysadmins

Adapt PRTG individually and dynamically to your needs and rely on a strong API:- HTTP API: Access monitoring data and manipulate monitoring objects via HTTP requests

- Custom sensors: Create your own PRTG sensors for customized monitoring

- Custom notifications: Create your own notifications and send action triggers to external systems

- REST Custom sensor: Monitor almost everything that provides data in XML or JSON format

We asked: would you recommend PRTG?

Over 95% of our customers say yes!

Paessler conducted trials in over 600 IT departments worldwide to tune its network monitoring software closer to the needs of sysadmins.

The result of the survey: over 95% of the participants would recommend PRTG – or already have.

Still not convinced?

More than 500,000

sysadmins love PRTG

Paessler PRTG is used by companies of all sizes. Sysadmins love PRTG because it makes their job a whole lot easier.

Monitor your entire IT infrastructure

Bandwidth, servers, virtual environments, websites, VoIP services – PRTG keeps an eye on your entire network.

Try Paessler PRTG

for free

Everyone has different monitoring needs. That’s why we let you try PRTG for free.

Start predictive maintenance with the help of PRTG and see how it can make your network more reliable and your job easier.

|

PRTG |

Network Monitoring Software - Version 25.1.104.1961 (April 7th, 2025) |

|

Hosting |

Download for Windows and cloud-based version PRTG Hosted Monitor available |

Languages |

English, German, Spanish, French, Portuguese, Dutch, Russian, Japanese, and Simplified Chinese |

Pricing |

Up to 100 sensors for free (Price List) |

Unified Monitoring |

Network devices, bandwidth, servers, applications, virtual environments, remote systems, IoT, and more |

Supported Vendors & Applications |

|