Industry 4.0, smart manufacturing, IIoT … the digitalization of production plants, particularly the factory floor, has revolutionized the industrial sector. The increased interconnectivity involved in all processes makes it crucial to have a central overview of your entire infrastructure.

The Industrial Internet of Things is an integral part of the modern factory, which has IIoT sensors just about everywhere to collect data about machines, HVAC systems, and more. And, just like other components in your industrial infrastructure, the IIoT sensors and gateways that record and transmit data, as well as their interconnectivity, need to be monitored to keep everything up and running.

Do you want to have a full overview of your OT environment in your supervisory and control systems – including traditional IT network components like routers, switches, firewalls, and more?

PRTG OPC UA Server consolidates monitoring data from your OT network and the IIoT in your control system. View all your data in one place for centralized monitoring and alarms.

Diagnose issues with your IIoT infrastructure by continuously monitoring the health and availability of your IIoT sensors, edge gateways, IT hardware, applications, connectivity, and more. Show monitoring data in real time and visualize it in graphic maps & dashboards to identify problems more easily. Gain the visibility you need to troubleshoot issues before they become critical.

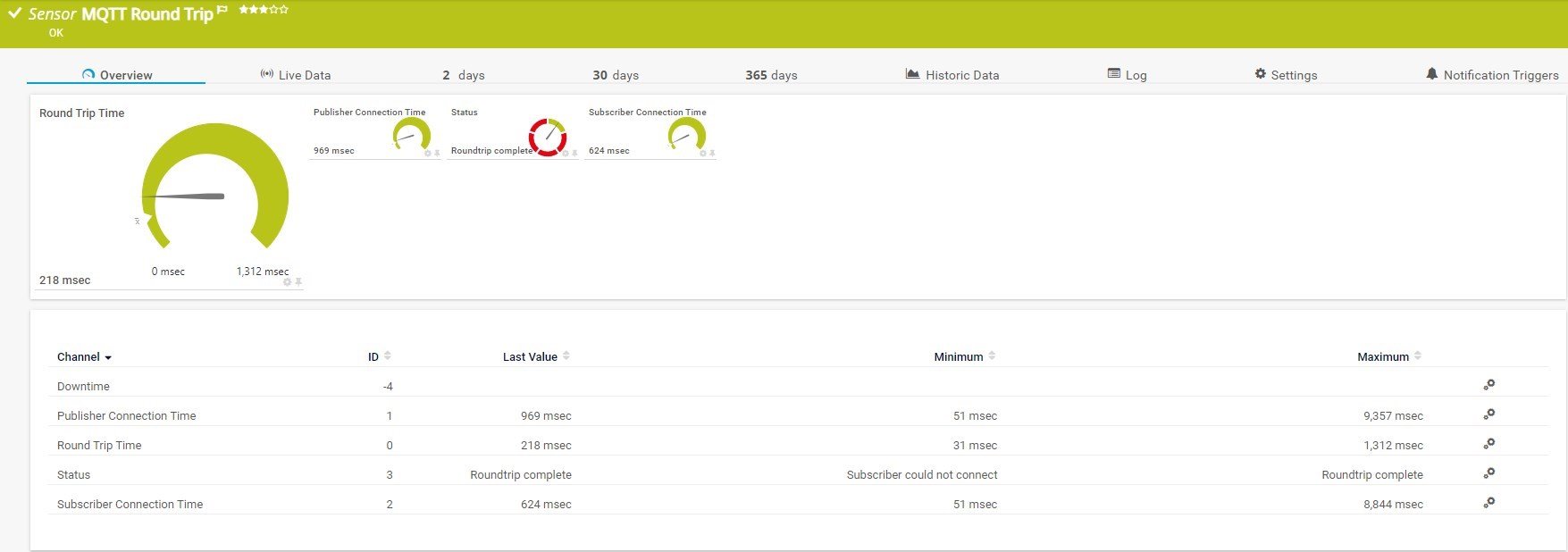

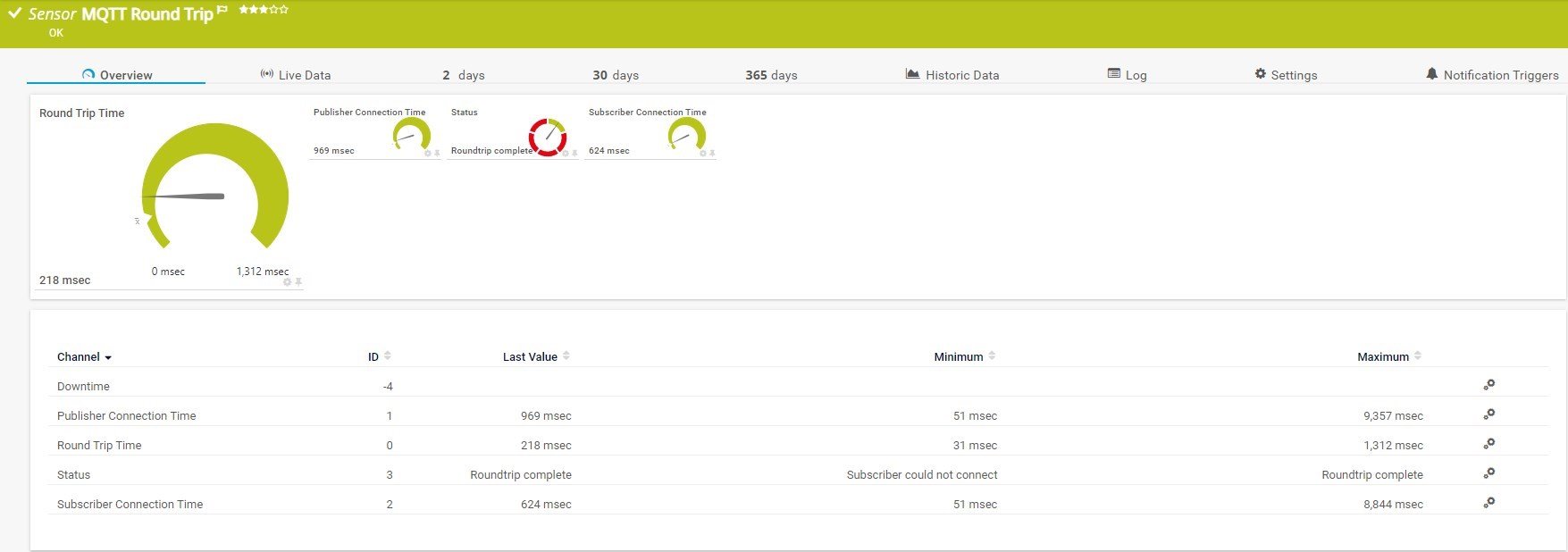

Preconfigured MQTT Round Trip sensor in PRTG

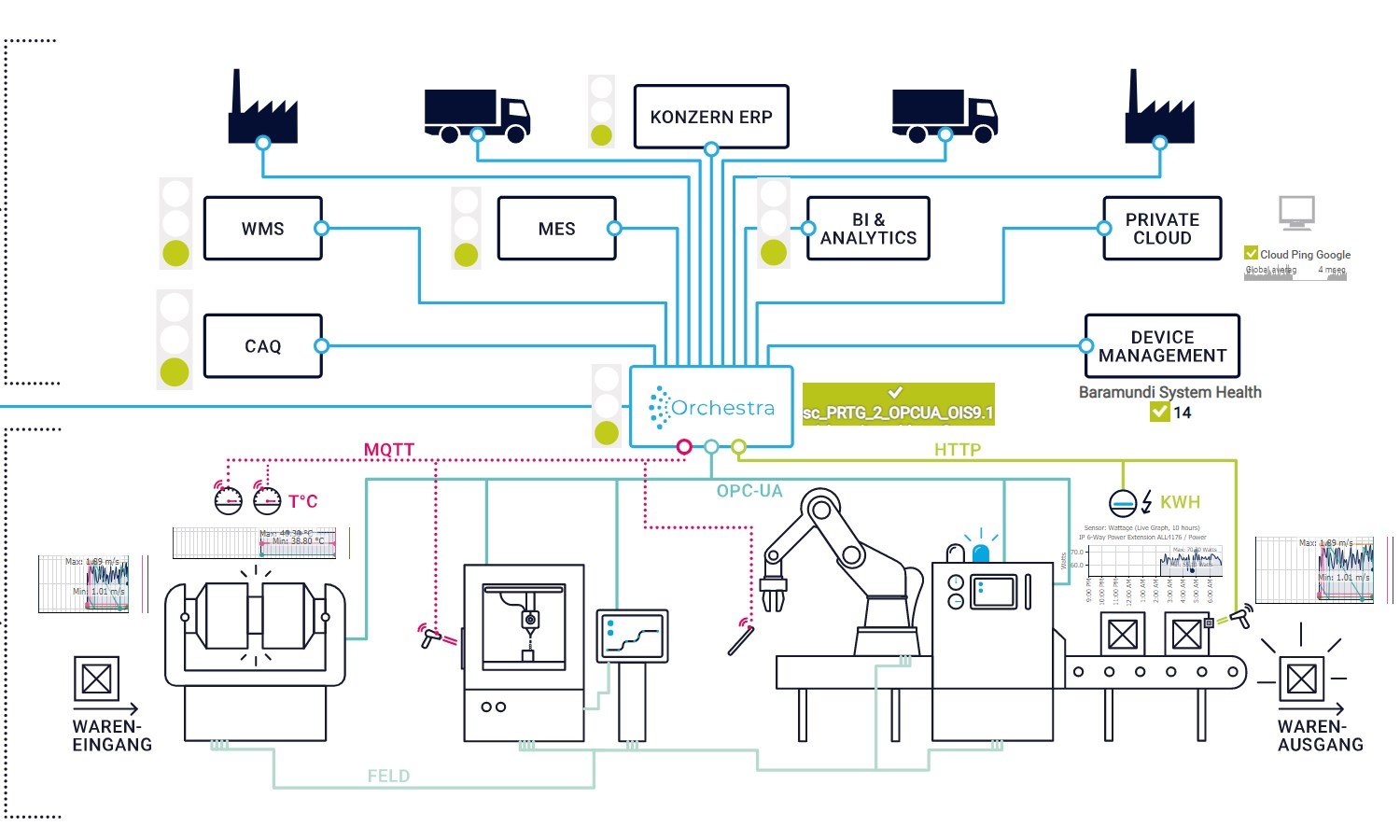

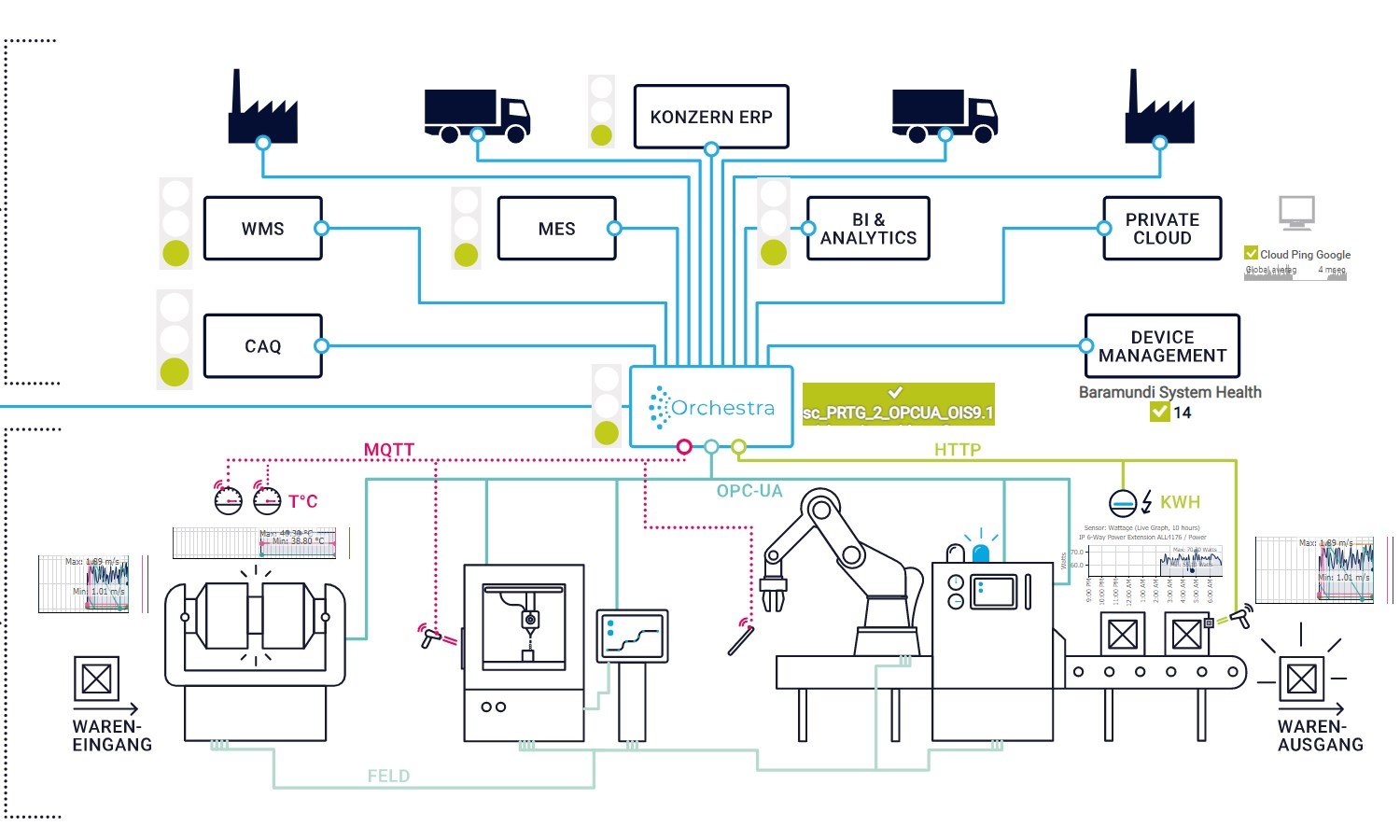

Custom PRTG map for visualizing industrial IT and IIoT processes

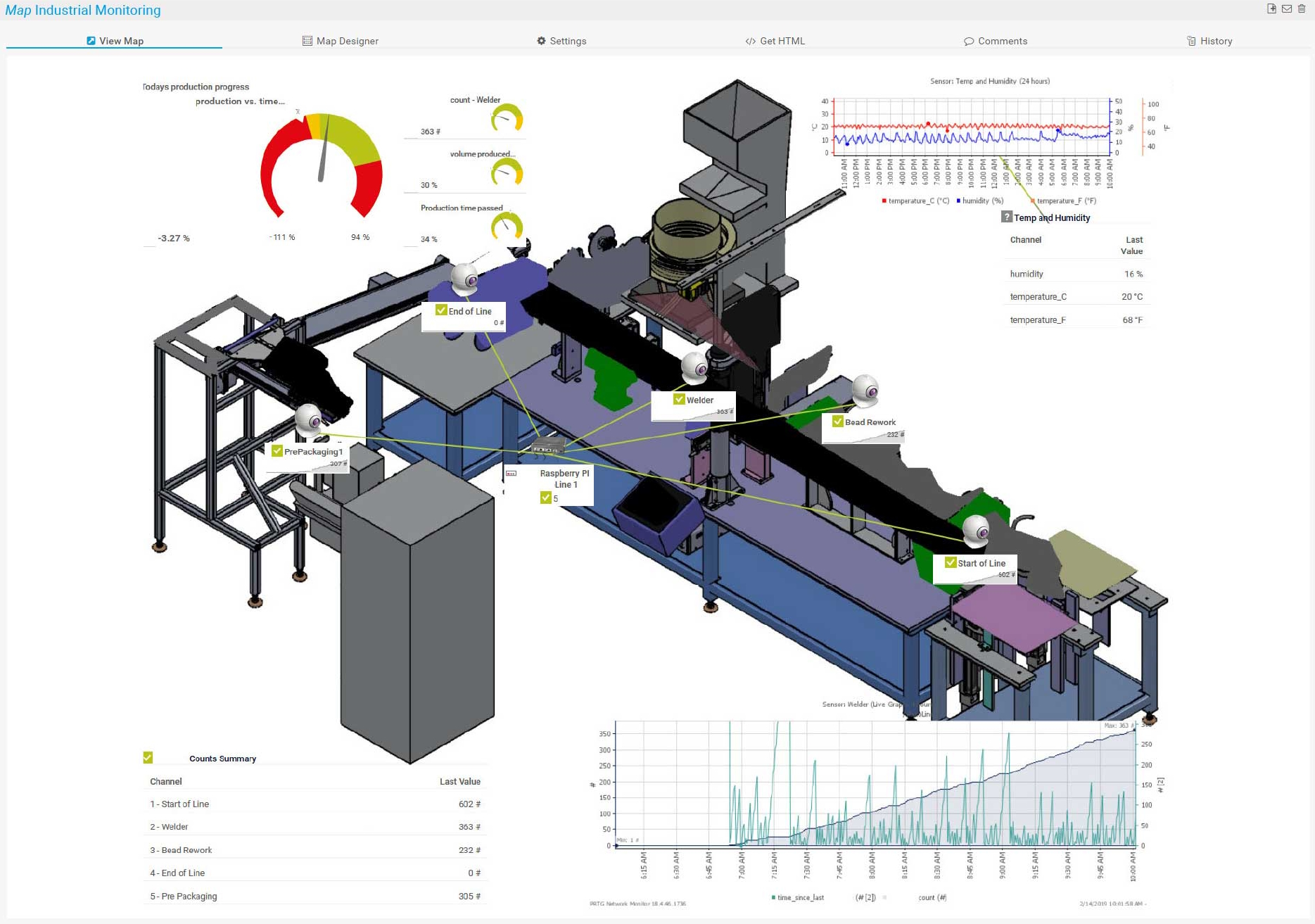

Keeping an eye on your production line with PRTG

Preconfigured MQTT Round Trip sensor in PRTG

Custom PRTG map for visualizing industrial IT and IIoT processes

“Great interface, intuitive, full REST support. custom scripts, rest sensors add extra value. We have been using PRTG for 10 years now in multiple environments and use cases. it has by far the best interface and very easy to setup without prior experience.”

Beyond out-of-the-box integrations for all classic IT standards, PRTG offers a REST API as well as JSON, OPC UA, Modbus, and MQTT support. Easily integrate OT components, IoT hardware sensors, as well as IT devices and applications with our preconfigured PRTG sensors.

See the PRTG Manual for a list of all available sensor types.

Companies around the world trust PRTG Network Monitor when it comes to ensuring that their IT systems run smoothly.

F.T.P. has 20 years of experience providing IT consulting to the most established automotive companies in Italy’s Motor Valley. System integration, cyber security, managed services, and industrial technology are their main areas of expertise. From a strong focus on the enterprise environment to the world of SMEs: F.T.P. offers high-value monitoring services through PRTG and enters new markets, including OT.

For more than 60 years, Michigan-based Kennedy Industries has helped municipalities across the state keep water clean and available to residents with its pumps, valves, repair, field service, controls and specialty products for water and wastewater facilities. They monitor more than 500 unique locations across the state with PRTG.

The food and beverage group Carambar & Co was founded in May 2017. To run this new company of more than 1000 employees, an Information System had to be created from scratch with an on-site SAP ERP and a number of applications in the cloud. To stabilize, improve the reliability, and optimize the performance of the system, the company decided to install PRTG as their IT monitoring solution.

In modern industrial IT, the right teams need the right data. Our guide shows how to implement holistic monitoring that brings elements from IT, OT and IIoT into your dashboards.

Our second guide gives you inspiration and ideas for dashboards that feature IT, OT and IIoT data – all in one place. We show you what truly convergent industrial dashboards look like!

Partnering with innovative IT vendors, Paessler unleashes synergies to create

new and additional benefits for joined customers.

PATLITE, as a manufacturer of visual and audible signaling devices, uses Paessler PRTG to ensure smooth plant operations.

Rhebo and PRTG offer a comprehensive monitoring solution for IT and OT environments: from condition monitoring through to anomaly and threat detection.

Siemon and Paessler bring together intelligent building technology and advanced monitoring and make your vision of intelligent buildings and data centers become reality.

Read about the Industrial Internet of Things as an integral part of Industry 4.0, typical IIoT architecture, what the IIoT is used for, and the monitoring of IIoT sensors themselves.

Listen to our podcast in which Roger Light, the creator of Eclipse Mosquitto MQTT broker, speaks about how he started Mosquitto and how he watched it – and the IoT – grow exponentially over the years.

Read about industrial retrofitting and how PRTG easily integrates with our Alliance Partner Skysens’s software platform, which works with endpoint and gateway devices from all the leading IoT/IIoT brands.

The IIoT, Industrial IoT, or Industrial Internet of Things, refers to IoT technology used in industrial environments. Its main goal is to collect data about the factory floor and facilities. This data can either be used to trigger manufacturing events, or be analyzed in external systems (like ERP systems) to further optimize and automate the production processes.

IIoT sensors can measure everything from vibration levels and the number of motor rotations to air temperature and the geographic location of equipment.

There is a broad range of IIoT sensor functionality that caters to many requirements or use cases. Here are some examples of IIoT sensor types and what they can be used for in manufacturing.

Environmental sensors

Used to monitor environmental conditions of machines, industrial enclosures, server rooms, and entire areas. These sensors can be used to maintain a safe environment for workers (for example by monitoring air quality or checking for dangerous gases), ensure optimal conditions for equipment (ensuring operating temperatures remain within reasonable temperatures or that humidity is not too high), or indicate when there was a failure (for example by checking for water leaks or rising temperatures).

Accelerometer sensors

Used to sense or measure changes in velocity. This can either be linear acceleration (velocity change in a single direction) or centrifugal acceleration (velocity change caused by an object moving in a circle). In manufacturing, these are commonly used to measure vibration of rotating equipment, such as turbines, bearings, or fans.

Gyroscopic sensors

Used to measure the rotation of an object as well as its angular velocity. These sensors can help to determine the object’s orientation without having to actually observe it.

Inertial measurement unit sensors

Although not a class of sensors on its own, the term “inertial measurement units” refers to measuring an object’s orientation and velocity using a combination of output metrics from various sensors, such as from accelerometers and gyroscopes.

Location tracking sensors

Used to track the geographic location of an object. This is useful for tracking shipments, vehicles, machines, and more.

Available connectivity options are cellular, Wi-Fi, LPWAN (Low-Power Wide-Area Network), LoRaWAN (Long-Range Wide-Area Network), Zigbee, and Bluetooth. The connectivity that is used depends on the requirements and the available resources. For example, if data needs to be transmitted over long distances, then cellular – which has a range of over 100 miles – could be used. Zigbee provides low-power, low-data transmissions within 400 feet, and LoRaWAN is good for low-power devices communicating at larger distances.

Retrofitting in this context means that IIoT sensors are used to make older equipment “smart”. Many factories have machines that are not capable of connecting with external systems, or they only offer analogue transmission possibilities. However, replacing these machines can be costly and often unnecessary if the machines still function well. In this case, retrofitting machines with IIoT sensors that communicate machine data to external systems can be a cost-effective solution.

An IIoT sensor is a specialized hardware sensor designed for industrial applications. These sensors are equipped with the capability to collect data from the physical world, such as temperature, pressure, humidity, vibration, and other relevant parameters, and then transmit this data to a central system for analysis.

In PRTG, “sensors” are the basic monitoring elements and as such, part of our monitoring software. One sensor usually monitors one measured value in your network, for example the traffic of a switch port, the CPU load of a server, or the free space on a disk drive. On average, you need about 5-10 sensors per device.

Network Monitoring Software – Version 24.4.102.1351 (November 12th, 2024)

Download for Windows and cloud-based version PRTG Hosted Monitor available

English, German, Spanish, French, Portuguese, Dutch, Russian, Japanese, and Simplified Chinese

Network devices, bandwidth, servers, applications, virtual environments, remote systems, IoT, and more

Choose the PRTG Network Monitor subscription that's best for you